This is one step higher than the Common Rail system which is found in current generation of diesel engines and this technology is also called as the Unit Injector system. This kind of engines are normally found in VW Group engines which are tagged under the name of TDi.

Construction:

In simple the common rail system have one high pressure pump in common to all the cylinders whereas in the PD or unit injector system each cylinders will have an high pressure pump which is cam operated thus pressurizes the fuel and send’s them to the combustion chamber. The Injectors are coupled to an solenoid pump and thus they form a unit.

The above picture shows the construction of the Injector

In the common rail system there are four fuel lines arising from a common rail.And the common rail gets a common fuel line(High pressurized fuel) from the high pressure pump. The pump is driven by the toothed belt which is connected to the cam shaft.

How Do they Unit Injector System Work?

Solenoid as the name implies they are electronically controlled so precise fuel delivery and high pressure can be obtained. Attaining high pressure helps in better atomization of the fuel and thus better combustion and better environment and even better KMPL.

We can put the sequence of events in the following manner,

Filling the High pressure Chamber:

During the filling phase the pump piston moves up and thus increases the volume of the high pressure area and during this time the solenoid valve is not actuated,thus the fuel from the fuel lines flows into the high pressure side.

In the above picture as you can see due to the rotation of injection cam the pump piston is pulled up

Beginning of Pre Injection Cycle:

During this cycle the pump piston is pushed down by the injection cam shaft via roller type rocker arm as the result of this the pressure in the pump piston increases as a result of this the fuel from the high pressure chamber flows into the fuel supply line. The ECU then initiates the solenoid valve is pushed in to the seat and cuts off the incoming fuel as a result of which the pressure inside the high pressure chamber increases.

Since the pressure keeps increasing the chamber, the as a result the pressure keeps increasing the pressure exceeds the spring force as a result the injector needle is lifted and thus pre injection begins.

Due to the pressure difference in the chamber the injector spring is lifted and the Pre-Injection is done

Post Injector Cycle or Main Injection Cycle:

The main injection cycle is similar to that off Pre-Injection the injector seat is lifted off the seat and thus the fuel is sprayed and this time the solenoid is stayed open for a longer time so that more amount of fuel can be sprayed into the combustion chamber. The pressure keeps raising in the high pressure chamber and the solenoid is made to stay for a longer time so that it can inject more amount of fuel through injector nozzle.

The position of the solenoid is changed and its made to open for a longer time

Now,When the Solenoid is no longer actuated by the Engine control unit the main injection comes to an end and some of the fuel is sent back to the fuel return lines. Thus the main injection is completed.

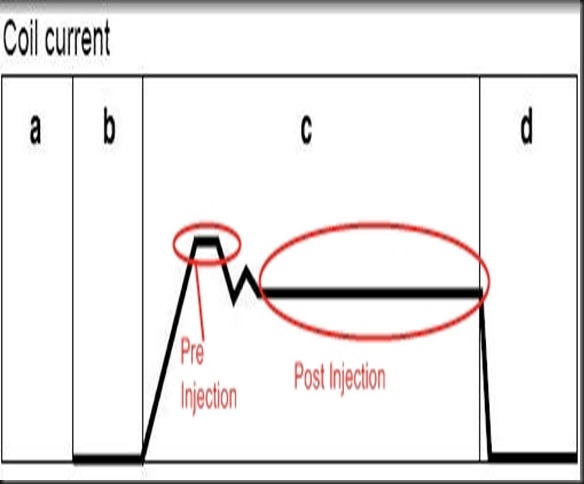

Coil Current During the various time of Injection

In the above picture we can understand that the coil current is higher when there is a initiation of the Pre-Injection and in the same time a constant current is given during the Post injection time to keep it open for a longer duration.