These days this word “Crossplane Crankshaft” is a very common word in MotoGP. Well in racing what does the rider look for???? The rider looks forward for three things Right power, right torque and a properly setup suspension to transform it on the track. More power, more torque and no proper suspension means there is no point in racing. A racing bike or a car is a combination of power and torque. Now consider power is given to the wheels when the driver demands it and how does he carrier it through out the race is based on the suspension. When the wheels are struck to the ground the driver gets the seventh sense of where exactly the grip is on the track…. So here lets discuss about the power factor.

So what Yamaha has done with an existing crankshaft, What makes the Yamaha M1 or the R1 now to get the maximum grip? Yamaha has developed a new generation of crankshaft called the “Crossplane crankshaft”. How does it help in getting the maximum grip,Well it changes the firing order of the engine just because the crankpin’s are offset between each other. Trust me this is not the only technology, there are several methods which is followed by Yamaha to get it such as YCCi(Yamaha Chip Controlled Intake), YCCT(Yamaha Chip Controlled Throttle) and the suspension set up etc.

Though this technology was present in the older generation “V” engines Yamaha gave life to this technology in their race engines which was driven by Rossi and Lorenzo. Recently Honda has also started using a similar technology in the new generation engines.

Crankshaft:

Well this is purely a mechanical part of the engine. According to me “ Its a part which converts the linear motion of the piston and connecting rod to the rotary motion of the flywheel ” and they also transmit the energy to the flywheel. Crankpin helps in achieving the desired firing order of the engine.

A four cylinder engine Crankshaft

We shall talk about the parts of the crankshaft later, First lets see what is Firing order,

Firing Order:

Firing order is nothing but deciding which cylinder should fire when based upon the engine configuration and design of forces that’s operating with the engine. A normal four stroke four cylinder engine will have a firing order of 1-3-2-4 or 1-4-3-2. There were some old engines existed with 1-2-3-4 firing order also. So, what is the common factor in deciding the firing order of the engine???? Well like I explained earlier it’s all based on the balancing of the primary and the secondary forces of the engine and provided it (the firing order) defines the application of the engine. A constant speed engine which is used in electrical application may have a very low forces acting on them because of a constant running speed and there is no other running or resisting medium such as roads, aerodynamic effects etc.

Parts of a crankshaft:

- Flywheel mounting flange is the place where the flywheel gets mounted to the crankshaft. They will have a “Dowel” for the easy location the holes where the bolts come and fit. These dowel helps in locating the holes through which there is no misalignment of the bolts.

- Crankpin oil hole is which the lubricating oil flows to the big end of the connecting rod. When the hole in the bearing and the hole in the crankpin are matched, lubricating oil flows from the crankshaft to the connecting rod.

- Counterweight’s are normally used to reduce the vibrations that are occurred when the piston moves in the cylinder. They also provide rigidity to the crankshaft.

- Main journals is the place where the connecting rod comes and fits. If its an Inline engine one connecting rod fits in the main journal and & in some V-Engines two connecting rods are also seen. A four cylinder inline engine will have five main journals.

- Crankweb connect the main journal to the crankpin’s.

- There are spaces at the end of the crankshaft from which the drive to the cam (through a belt drive) and the vibration dampers are taken.

Well the crosspane crankshaft’s design is purely based on changing the angles of the crankpin which will alter the firing angle respectively.

Crossplane Crankshaft:

Well how different is the crossplane crankshaft from others. What makes it so special?

Now, consider a normal four cylinder engine with an firing order of 1-3-4-2 and it runs on a four stroke cycle. In that case the engine will have a useful stroke (Power stroke) every 180 degrees of the crankshaft in each cylinders. That is first cylinder will fire at 180deg and then the next power stroke comes in the third cylinder after 180degrees. Thus they are interlinked and designed flat that for every 180degrees there is a power stroke or I can they are designed with an “Even Firing Order”.

Yamaha’s crossplane crankshaft has a “un-even firing order” that is the engine will not have firing order for every 180degrees. The crankshaft is designed to have an firing order of 270-180-90-180 degrees. That is the first cylinder will fire at 270degrees of crankshaft and the third followed by next 180degrees of crankshaft. This is the change what they made in the crankshaft to get an even flow of torque in the wheels. But why was this necessary when all the engines run on a even firing order in the world?

Crossplane Crankshaft Conventional Crankshaft

As you can see in the image in the crossplane crankshaft the pistons move individually and in the conventional two pistons move up and down because of the even crank design.

How torque is produced in a Engine?

Torque is nothing but the maximum force that the engine can produce within the specified range and it should not be mistaken for the Work output(Power) of the engine. Well coming on to the topic how the torque is produced, When the combustion in the engine happens due to mixture of air and fuel an external agent aids the firing then the fuel and the air burns and produces energy. This energy is passed on to the crankshaft, Flywheel, and to the gear box finally to the wheels. When the wheels rotate they produce torque or power from the requirement of the driver.

In simpler language I can say that,

Torque:- How fast you can hit the wall…

Power:- How long you can hit the wall…

Ok the torque in the engine is produced. Now for the next few meaningful definition lets jump in to bit of Engineering,

If the flywheel is very light and all other moving parts are light they spin faster which successively can produce more torque.

But on the other side if there is too much of weight within the moving parts they Spin slow because of the resistance what they have within themselves just because they are heavier leading to less torque produced. Well this is not the only factor there are many factors which limit the torque produced in the engine such as fuel limitations and engine’s other operating factors such as the maximum combustion pressure that the engine can hold etc.

So what ever be the part that rotates or moves simply subjected to any motion they produce certain amount of Inertia which is required to keep them performing the same action. Similarly in an engine to keep them rotating there should me a minimum amount of force which keeps the moving parts spinning. This is done by the combustion of the fuel.

Fine in that case I might as well have a lighter moving parts which requires low inertia. Why is crossplane crankshaft so special? Why such a complicated design is needed?

What exactly Happens?

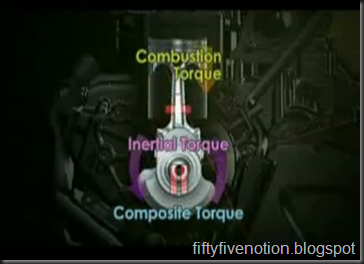

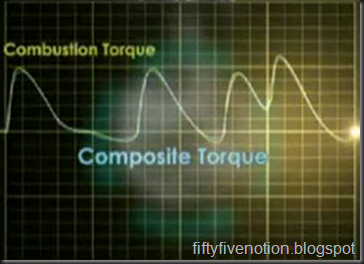

When the driver sends his demand through the throttle to the engine,what he gets as a output is the torque and power from the engine. The torque what he gets is the combination of “Combustion” and “Inertia” torque. Combustion torque is experienced by the burning of fuel and air mixture which is pretty straight forward. The inertia torque which the driver may not feel but what is gets is mainly due to the Inertia i.e. due to the motion of the moving parts in an engine.

Overall Torque = Combustion torque + Inertia Torque

The above image explains how the Combustion,Inertial and Composite torque are produced.

Only the combustion torque is felt by the driver but the inertia torque is not felt by the driver. Which means the combustion torque is controlled by the throttle from the driver and inertia torque is purely based on the speed of the crankshaft. Now due to which when the driver always feels that there is a slight delay in the flow of power to the wheels. This is purely because of the inertia torque produced in the engine. What the driver wants is the combustion torque but he gets in the combination of the combustion and inertia torque. The reason why people are working to eliminate

Four Stroke Working Cycle

Now why is this inertia torque is so critical… What makes it so complicated… Well when the crank moves up and down it travels faster during their top and bottom movement. But they are travel very slow when they are in 90 and 270 degrees, its purely because @ 90 and 270 degrees the whole of the piston and the connecting rod weight is pushing the counter weight to move further. Its extremely opposite in the other side to push the counter weight down the engine has to give a little effort and the rest is taken care by the gravity. So if you consider at the 90 and 270 degree positions its purely because of the inertia of the moving parts. So this delay is proportional to the speed of the crankshaft. At higher speeds they are very critical. What exactly happens is the driver wants the combustion torque and since the crank train is spinning faster the output will be the combination of the inertia and the combustion torque. So the driver gets a unpleasant surprise when he revs the engine. This unpleasant surprise can be felt in higher rpm’s especially in motorsport engine when they rev for more than 19000rpm.

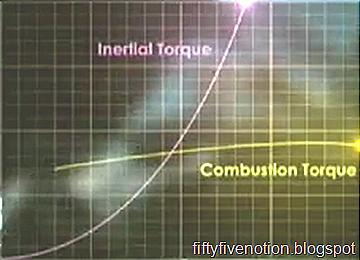

Inertial torque goes proportional to the speed and the combustion torque goes proportional with the drivers demand

So what did the Yamaha do to keep the inertia torque low? Well if you see the picture of the normal crankshaft below two cylinders either cylinder 1 or 4 or cylinder 2 and 3 based on the firing order. Since they move together the crank web and the counter weight match the other cylinder movement. In this case it’s really hard for the engine to reduce the inertia torque because of the movement of the other cylinder and they strain a bit mainly due to the all the counterweight force acting on one side.

Normal Crankshaft Crossplane Crankshaft

Yamaha made the position of the other cylinder’s counter weight exactly to the opposite side. Refer to the picture below (Crossplane crankshaft) so if the 3rd cylinder movement is slow in 90 degree position the other cylinder counter weight will be exactly opposite to the other so that it forces the 3rd cylinder movement to revolve faster. Due to this small shift in the position of the crankpins Yamaha was completely able to avoid the Inertia torque.

Due to the new alignment the Inertial torque is completely avoided Honda’s global crankshaft design

Interestingly Honda also adopted this new technology in their crank designs for the 700cc engine. Though these kind of crankshafts are higher in terms of the manufacturing cost when compared to the older one since their advantages are on the higher side every manufacturer particularly in the bike segment are coming forward for this old technology which has been existing for a long time. Yamaha claims that the bike is much better in high speed corners than the old one. Surprisingly Yamaha claims there is a significant increase in the tire life also. But Yamaha and Honda has used a secondary balancer shaft to reduce the secondary vibrations of the engine. May be in the near future we can see all cars even come with an un-even firing order to increase the drivability mainly for smaller engines.

The following videos explain the working of the crossplane crankshaft system